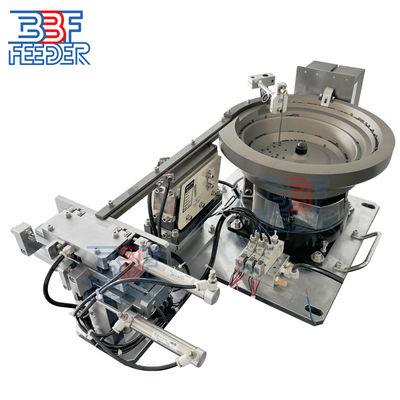

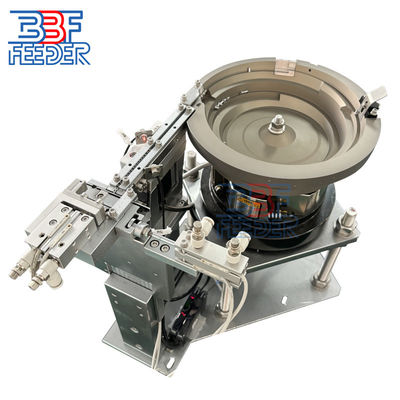

Máy cấp liệu rung dạng mâm xoay nhà máy Trung Quốc CE Tùy chỉnh Máy cấp liệu tự động

1. Mô tả:

Máy cấp liệu rung dạng mâm được sử dụng rộng rãi trong sản xuất công nghiệp, đặc biệt trong các lĩnh vực đòi hỏi vận chuyển hàng loạt các bộ phận. Ứng dụng của chúng trải dài trên nhiều ngành công nghiệp, chẳng hạn như ô tô, mỹ phẩm, thực phẩm, thời trang, dược phẩm, điện tử tiêu dùng, linh kiện điện, nhựa và nhiều ngành khác.

Một ứng dụng quan trọng của máy cấp liệu rung dạng mâm là trong việc vận chuyển các chai và nắp nhỏ. Chúng có khả năng chuyển các mặt hàng này đến dây chuyền sản xuất tiếp theo với tốc độ 90 đơn vị mỗi phút. Đối với việc sản xuất các sản phẩm đóng chai, máy cấp liệu rung dạng mâm đã trở thành những thành phần không thể thiếu của dây chuyền sản xuất tự động. Bằng cách cung cấp cho các doanh nghiệp một giải pháp sản xuất tự động hiệu quả về chi phí, chúng đóng một vai trò quan trọng trong việc tăng đáng kể năng suất đồng thời giảm chi phí sản xuất.

2. Thông số kỹ thuật:

| Tên sản phẩm |

Máy cấp liệu rung dạng mâm |

| Vật liệu |

Nhôm (AL7075), Thép không gỉ (SUS304) hoặc Dựa trên Yêu cầu của Khách hàng |

| Bộ điều khiển |

CUH, Sanki, Sinfonia, REO, Afag |

| Điện áp |

220V 50HZ/110V 60Hz hoặc Dựa trên Yêu cầu của Khách hàng |

| Công suất |

300W/500W/1000W/1500W/2000W |

|

Màu sắc

|

Xanh lục hoặc Dựa trên Yêu cầu của Khách hàng |

| Dịch vụ sau bán hàng |

Phụ tùng và Hỗ trợ Công nghệ |

| Bảo hành |

2 năm |

| Chứng nhận |

CE, ISO9001, ROHS |

| Thời gian giao hàng |

3 Tuần làm việc |

3 . Ứng dụngcủaMáy cấp liệu rung dạng mâm :

Máy cấp liệu rung dạng mâm thường được sử dụng để vận chuyển kẹo và các loại đồ ăn nhẹ khác. Công ty chúng tôi đã từng phát triển một máy cấp liệu rung dạng mâm chuyên dụng để vận chuyển kẹo cho một khách hàng Mỹ, và đã nhận được phản hồi tích cực từ khách hàng.

Khi vận hành máy cấp liệu rung dạng mâm cho mục đích này, các thông số chính của nó — chẳng hạn như biên độ và tần số — phải được điều chỉnh đến mức tối ưu. Điều này rất quan trọng để ngăn chặn rung động quá mức, nếu không có thể khiến kẹo va vào nhau và bị mòn hoặc hư hỏng.

Về việc lựa chọn vật liệu cho lớp phủ bề mặt của máy cấp liệu, chúng tôi nghiêm ngặt chọn các vật liệu đạt chuẩn thực phẩm. Sự lựa chọn này được thiết kế để loại bỏ nguy cơ nhiễm hóa chất có thể ảnh hưởng đến kẹo trong quá trình vận chuyển. Ngoài ra, vì việc vận chuyển thực phẩm đòi hỏi một môi trường sạch sẽ, chúng tôi khuyên bạn nên trang bị cho máy cấp liệu rung dạng mâm một nắp đậy bụi để duy trì các tiêu chuẩn vệ sinh.

Để đáp ứng yêu cầu cụ thể của khách hàng về việc đóng gói mười viên kẹo mỗi hộp, các kỹ sư của chúng tôi đã tích hợp một chức năng đếm vào máy cấp liệu rung dạng mâm. Với chức năng này được kích hoạt, máy cấp liệu sẽ tự động ngừng rung khi mười viên kẹo đã được vận chuyển. Sau một khoảng thời gian ngắn, nó sẽ tiếp tục hoạt động để tiếp tục quá trình cấp liệu, đảm bảo việc đếm kẹo chính xác và hiệu quả để đóng gói.

4. Thêm hình ảnh: