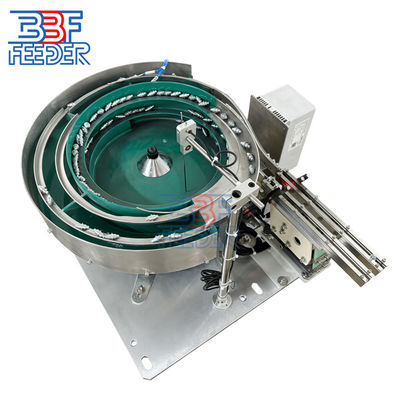

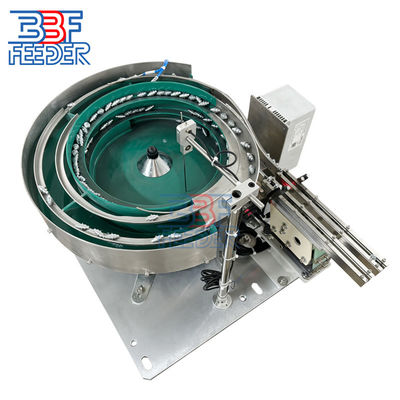

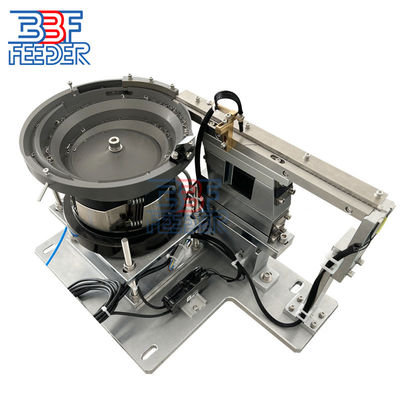

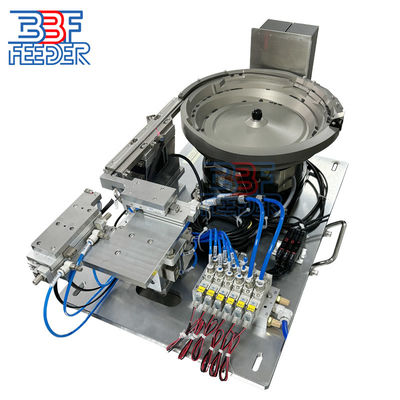

Bộ nạp vít chính xác cao, có thể điều chỉnh tần số, bộ nạp bộ phận bằng thép không gỉ

1. Mô tả:

Bộ nạp rung có thể cung cấp một giải pháp thay thế hiệu quả về chi phí cho lao động thủ công và tối ưu hóa quy trình sản xuất. Bộ nạp rung được sử dụng trong nhiều ngành công nghiệp bao gồm dược phẩm, y tế, thực phẩm, ô tô và các sản phẩm tiêu dùng.

Bộ nạp rung sử dụng rung để định hướng và vận chuyển các bộ phận có hình dạng và trọng lượng khác nhau, chẳng hạn như ốc vít, đai ốc, vòng đệm, v.v., tăng năng suất và giảm khả năng xảy ra lỗi của con người.

Trong dây chuyền sản xuất tự động, bộ nạp rung thường được sử dụng kết hợp với các thiết bị sản xuất khác, chẳng hạn như máy chiết rót và đóng gói tự động. Để cải thiện hơn nữa năng suất, các cơ chế gắp, camera và các thiết bị khác được thêm vào bộ nạp rung.

2. Thông số kỹ thuật:

| Tên sản phẩm |

Bộ nạp rung |

| Vật liệu |

Nhôm (AL7075), Thép không gỉ (SUS304) hoặc Dựa trên Yêu cầu của Khách hàng |

| Bộ điều khiển |

CUH, Sanki, Sinfonia, REO, Afag |

| Điện áp |

220V 50HZ/110V 60Hz hoặc Dựa trên Yêu cầu của Khách hàng |

| Công suất |

300W/500W/1000W/1500W/2000W |

|

Màu sắc

|

Xanh lục hoặc Dựa trên Yêu cầu của Khách hàng |

| Dịch vụ sau bán hàng |

Phụ tùng và Hỗ trợ Công nghệ |

| Bảo hành |

2 năm |

| Chứng nhận |

CE, ISO9001, ROHS |

| Thời gian giao hàng |

3 Tuần làm việc |

3 . Ứng dụngcủaBộ nạp rung :

Bộ nạp rung thường được sử dụng để vận chuyển kẹo và các đồ ăn nhẹ khác. Công ty chúng tôi đã từng phát triển một bộ nạp rung để vận chuyển kẹo cho một khách hàng người Mỹ và nhận được những nhận xét tốt từ khách hàng.

Khi sử dụng bộ nạp rung, các thông số của bộ nạp rung (biên độ, tần số, v.v.) cần được điều chỉnh đến mức thích hợp để tránh rung quá mức dẫn đến va chạm và mài mòn kẹo. Trong việc lựa chọn lớp phủ trên bề mặt của bộ nạp rung, chúng tôi sẽ chọn vật liệu cấp thực phẩm để tránh ô nhiễm hóa học của kẹo trong quá trình vận chuyển. Vận chuyển thực phẩm phải ở trong môi trường sạch sẽ, chúng tôi khuyên bạn nên thêm nắp đậy bụi cho bộ nạp rung.

Để đạt được yêu cầu của khách hàng là mười viên kẹo bên trong một hộp, các kỹ sư đã thêm chức năng đếm vào bộ nạp rung, sau khi mười viên kẹo được vận chuyển, bộ nạp rung sẽ ngừng rung và bắt đầu hoạt động trở lại sau một khoảng thời gian.

4. Thêm hình ảnh: